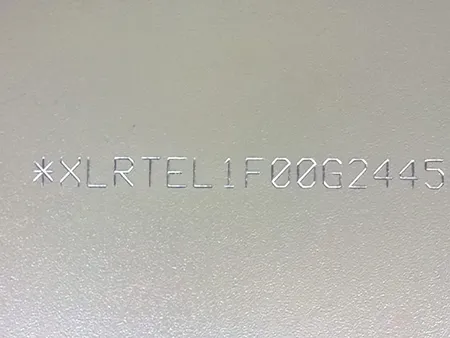

For over 10 years, Pryor has been at the forefront of VIN marking applications for the automotive industry. In 2020 this culminated in Pryor winning the coveted Queens Award for Innovation in recognition of the work done with Jaguar Land Rover. Through this period we have gained extensive knowledge and experience of VIN marking requirements, specifications, and solutions.

Our expertise in this field has meant we are the chosen partner of many global Automotive OEMS for bespoke, fit for purpose VIN marking systems.

Overview

Pryor have become the industry leader in supplying VIN marking systems to Automotive OEMs and are at the cutting edge of implementing bespoke, innovate and high speed marking systems for our customers.

Depending on the OEMs specifications, we’re able to adapt and offer a marking system that is suitable for our customer’s requirements, cycle time and budget. Most VIN engraving systems take the form of either a completely automated robotic cell, or a manipulator assisted system, which is docked and clamped on to the vehicle body.

We have the experience in providing VIN marking systems for a large variety of vehicles including; cars, electric cars, trucks and buses, motorbikes and off road vehicles to name a few!

Each project we work on presents a new engineering challenge. We have the in-house capability to rise to this challenge and deliver our customer a solution.

Overview

Pryor have become the industry leader in supplying VIN marking systems to Automotive OEMs and are at the cutting edge of implementing bespoke, innovate and high speed marking systems for our customers.

Depending on the OEMs specifications, we’re able to adapt and offer a marking system that is suitable for our customer’s requirements, cycle time and budget. Most VIN engraving systems take the form of either a completely automated robotic cell, or a manipulator assisted system, which is docked and clamped on to the vehicle body.

We have the experience in providing VIN marking systems for a large variety of vehicles including; cars, electric cars, trucks and buses, motorbikes and off road vehicles to name a few!

Each project we work on presents a new engineering challenge. We have the in-house capability to rise to this challenge and deliver our customer a solution.

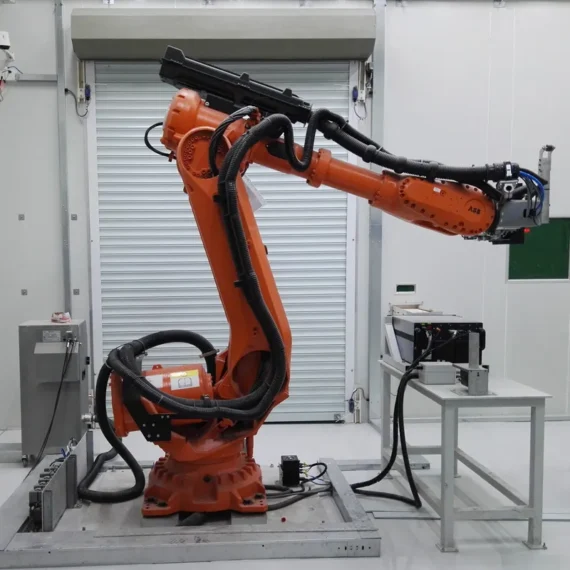

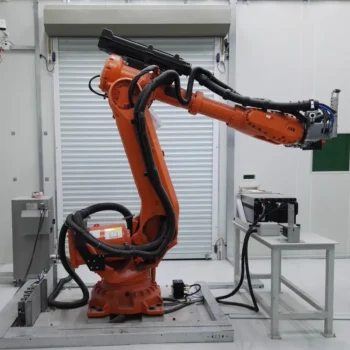

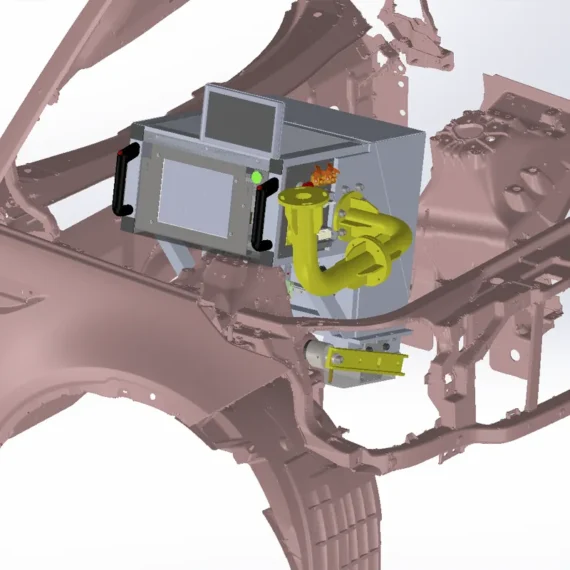

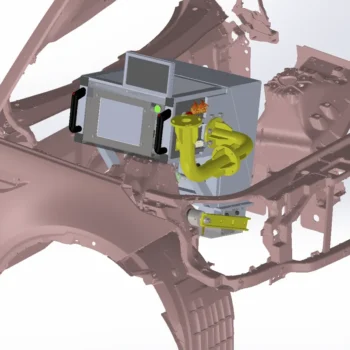

Robotic VIN Marking

Our Robotic VIN marking systems provide the greatest level of automation. We have the skills to design and manufacture custom end effectors to suit specific vehicle marking positions. We regularly integrate vision systems to aid laser head guidance and offer VIN OCR and OCV, post marking.

For ultimate flexibility and future proofing, we can house the entire robotic marking operation in a laser safe enclosure, allowing a generic end effector to mark in any position, or multiple positions, on any vehicle.

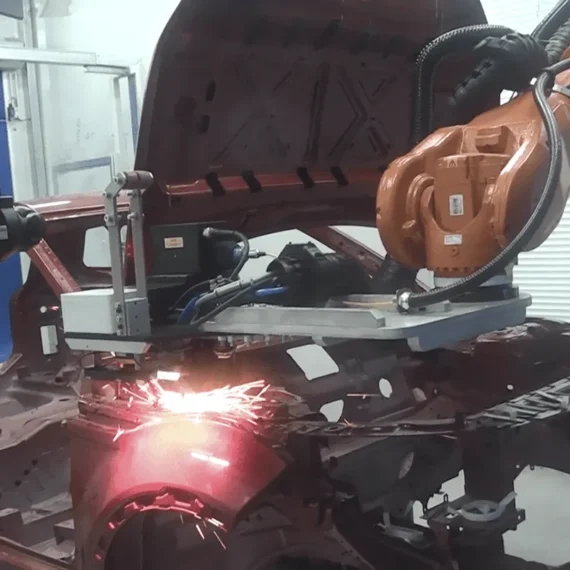

We revolutionised High Power Laser VIN Marking with Jaguar Land Rover in 2013 and have gone on to deliver many marking systems utilising this technology in the UK and oversees.

Read the JLR Case Study here.

Our experience and knowledge of scribe and dot-peen marking technology, which are more of a mechanical method, can also be utilised in robotic VIN applications.

Robotic VIN Marking

Our Robotic VIN marking systems provide the greatest level of automation. We have the skills to design and manufacture custom end effectors to suit specific vehicle marking positions. We regularly integrate vision systems to aid laser head guidance and offer VIN OCR and OCV, post marking.

For ultimate flexibility and future proofing, we can house the entire robotic marking operation in a laser safe enclosure, allowing a generic end effector to mark in any position, or multiple positions, on any vehicle.

We revolutionised High Power Laser VIN Marking with Jaguar Land Rover in 2013 and have gone on to deliver many marking systems utilising this technology in the UK and oversees.

Read the JLR Case Study here.

Our experience and knowledge of scribe and dot-peen marking technology, which are more of a mechanical method, can also be utilised in robotic VIN applications.

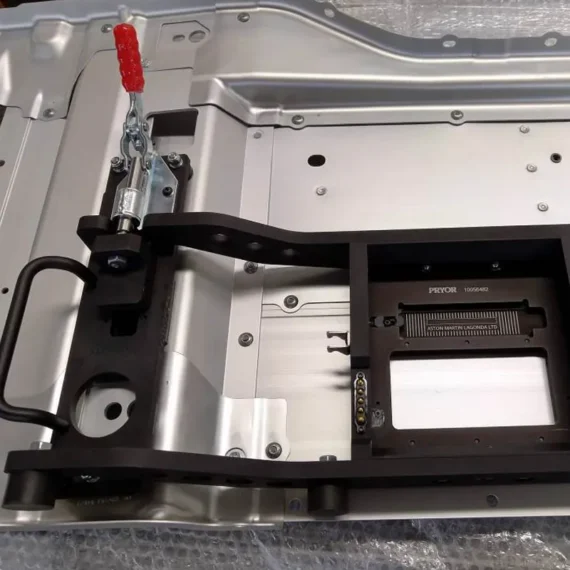

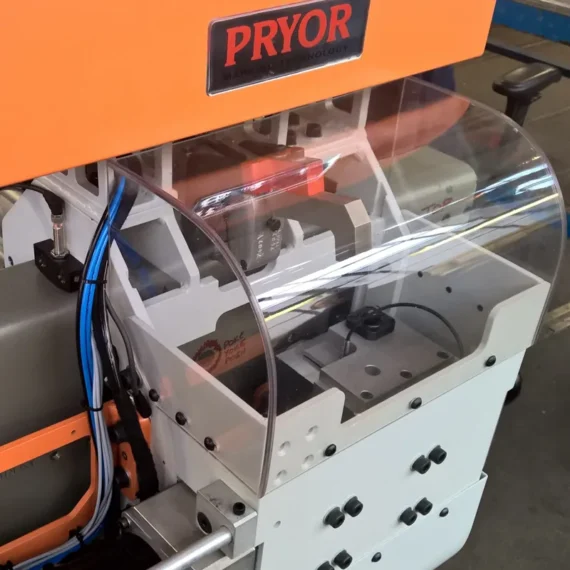

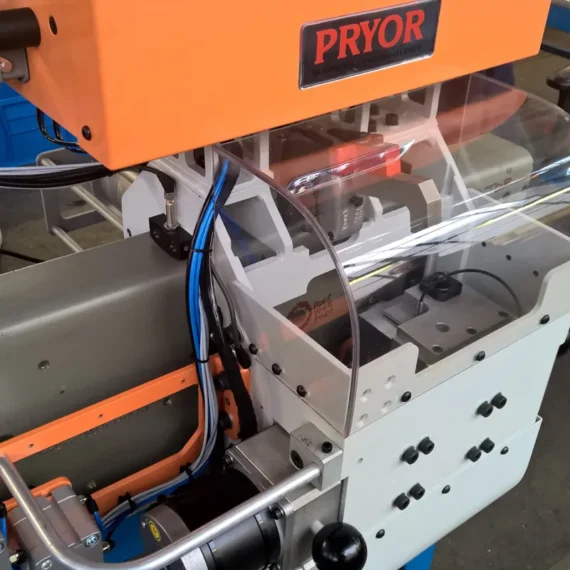

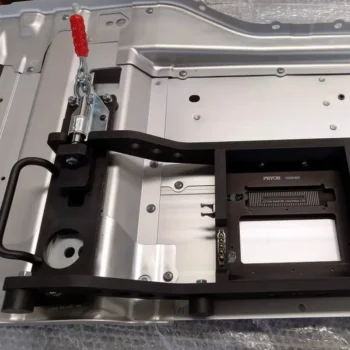

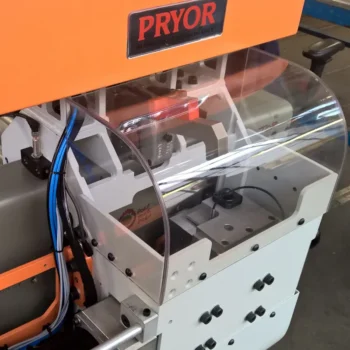

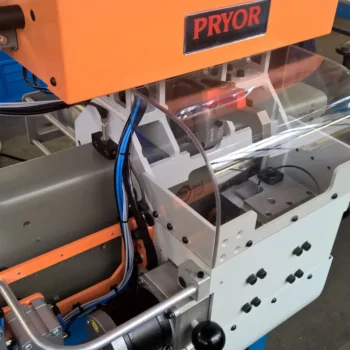

Manipulator Assisted System

Our manipulator assisted systems are generally utilised for lower cycle time production lines, or where there is insufficient space or budget for a full robotic cell. These systems are also ideal as a cost saving, emergency backup strategy to a robotic cell.

We are capable of integrating our high power lasers in these systems, which involves the design and manufacture of a custom shrouding and clamping arrangement, to allow consistent and safe mark placement.

If it is necessary for a manipulator based laser marking system to cover a range of VIN mark positions or vehicle models; we can design various interchangeable end effector tooling and shrouding, with the ability to quickly changeover the tool at the side of the production line,

Our scribe and dot-peen technology can also be utilised for manipulator based marking systems, where a lower cost system is required.

Manipulator Assisted System

Our manipulator assisted systems are generally utilised for lower cycle time production lines, or where there is insufficient space or budget for a full robotic cell. These systems are also ideal as a cost saving, emergency backup strategy to a robotic cell.

We are capable of integrating our high power lasers in these systems, which involves the design and manufacture of a custom shrouding and clamping arrangement, to allow consistent and safe mark placement.

If it is necessary for a manipulator based laser marking system to cover a range of VIN mark positions or vehicle models; we can design various interchangeable end effector tooling and shrouding, with the ability to quickly changeover the tool at the side of the production line,

Our scribe and dot-peen technology can also be utilised for manipulator based marking systems, where a lower cost system is required.

Performance

Laser

~ 4 – 12 Seconds

Scribe

~ 30 seconds

Dot-Peen

~ 40 seconds

“Since the start of 2013, robotic marking systems have become the company’s expertise and in 2014 (*and 2021) they were awarded the prestigious industry prize for innovation for their work with a major automotive player in developing a turnkey robotic VIN cell.”

Process, Engineering & Control Magazine