Ensuring the traceability of products within a manufacturing production line is essential for keeping track of quality control and maintaining the standards that your organisation is proud of. Our standard traceability software is a comprehensive, powerful application, but we know from experience that it is impossible for us to cover all possible applications and requirements with a single piece of software. This is why we offer complete bespoke part marking software development so that you can implement the solution that meets your requirements.

Overview

Our software started as a fairly simple program to to run our marking machines via a Windows interface, but we quickly realised that combined with a marking machine it was capable of so much more. Today our software is used to tie together the different aspects of the marking process and, increasingly important, to integrate the marking equipment into a manufacturing execution system (MES).

We have a team of software developers on hand to modify and create new features within the software and build a bespoke system that can then easily integrate into you network.

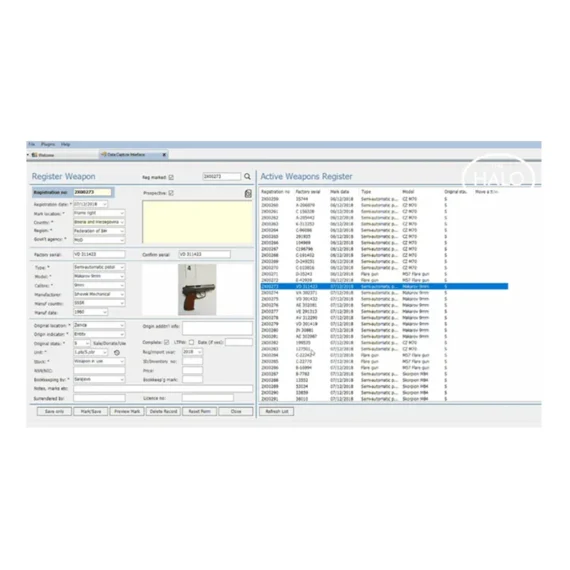

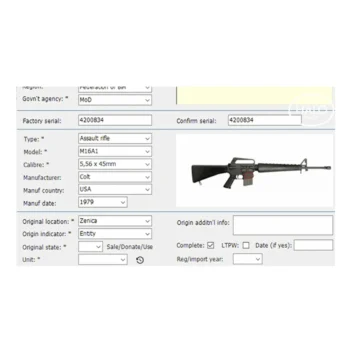

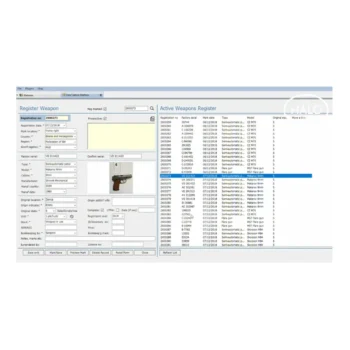

Behind our software is a flexible databasing function to collect data about the marking cycle. For our customers we regularly expand this database to collect data from other process and store it against the unique serial number applied during marking. This can then be used to create a component passport for every part within the process. Options include:

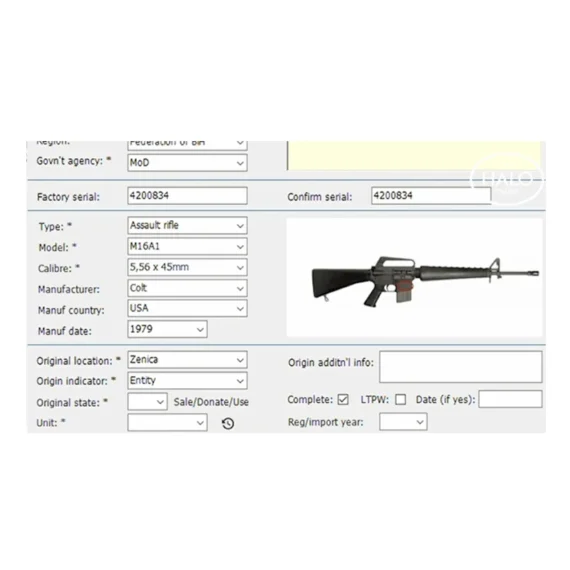

- Custom operator input pages

- Complete network integration and communication with a MES

- Custom database applications

- Manufacturing gate-control

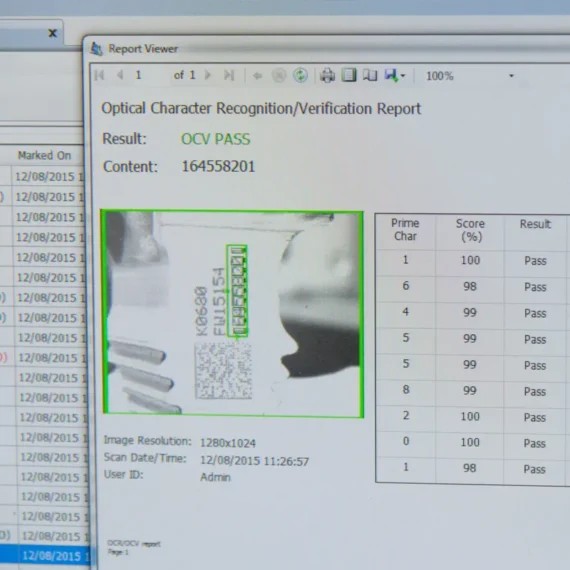

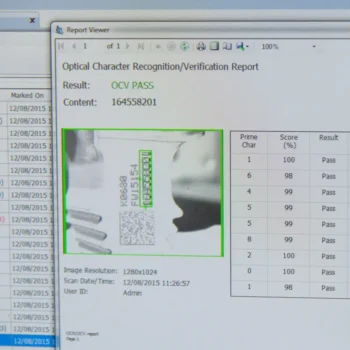

- Communication with other equipment for data input

See our Case Studies area for examples of previous work

Overview

Our software started as a fairly simple program to to run our marking machines via a Windows interface, but we quickly realised that combined with a marking machine it was capable of so much more. Today our software is used to tie together the different aspects of the marking process and, increasingly important, to integrate the marking equipment into a manufacturing execution system (MES).

We have a team of software developers on hand to modify and create new features within the software and build a bespoke system that can then easily integrate into you network.

Behind our software is a flexible databasing function to collect data about the marking cycle. For our customers we regularly expand this database to collect data from other process and store it against the unique serial number applied during marking. This can then be used to create a component passport for every part within the process. Options include:

- Custom operator input pages

- Complete network integration and communication with a MES

- Custom database applications

- Manufacturing gate-control

- Communication with other equipment for data input

See our Case Studies area for examples of previous work

“For customers handling large volumes, automating the loading and unloading of parts into the marking cell is a great option. We have countless examples of customers who have improved their marking process and efficiencies by implementing such a system.”

Darren | Sales